Low-hanging Fruits in Sales, Cashflow & Efficiency

When all CPG manufacturers are working hard to capture decreased spending from their customers, success hinges on maximizing sales, streamlining operations, and ensuring a healthy cash flow. While there’s no magic bullet, a strategic focus on three key areas can yield significant benefits: assortment rationalization, planogram optimization, and automatic replenishment. These strategies, often referred to as the “CPG trifecta,” are low-hanging fruits that can be grasped by manufacturers of all sizes, delivering a powerful combination of increased sales, improved efficiencies, and flourishing cash flow.

1. Assortment Rationalization: Streamlining Your Product Lines

Imagine a production line with an overwhelming variety of product variations, or stores with over abundant choices of products. While this might seem like a diverse offering, it can lead to inefficiencies and increased costs. Assortment rationalization tackles this by focusing on a curated selection of products that resonate most with your target audience.

Benefits

Reduced Dead Stock: By eliminating slow-moving items, you free up valuable production capacity and reduce the amount of capital tied up in unproductive inventory. This translates to lower storage costs and the ability to invest in higher-demand products.

Improved Sales: A streamlined product line makes it easier for retailers and customers to choose, leading to a more positive experience and potentially increased orders.

Sharpened Focus: Focusing on core products allows for better analysis of customer buying habits and targeted promotions for maximum impact.

Decrease Returns: Focusing on core products allows much fewer costly returns.

Customer-Centric Approach: Understanding customer preferences through data analysis can help in creating a more targeted product assortment, which enhances customer loyalty and sales.

Sustainability Considerations: Many CPG manufacturers are now focusing on reducing their environmental footprint. Optimizing product lines to include sustainable options can appeal to environmentally conscious consumers and reduce waste.

Where We Can Help:

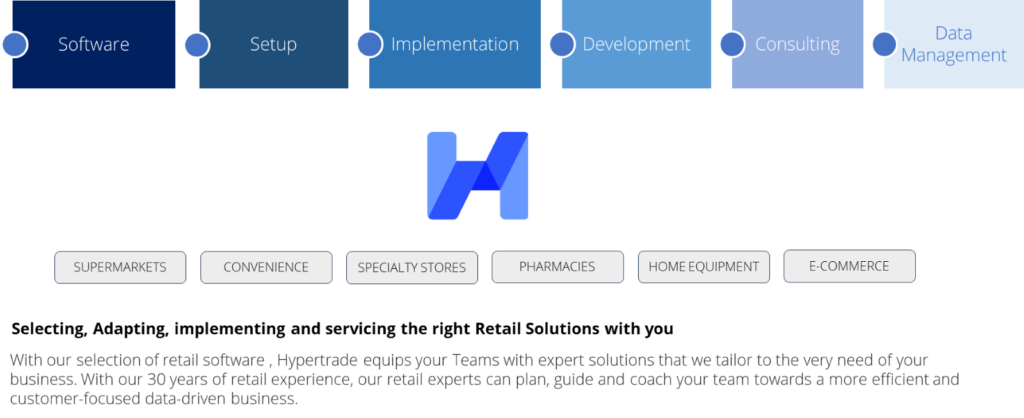

- Hypertrade’s Machine Learning Driven Assortment Optimization algorithm delivers quantified rationalization scenarios in minutes, using shopper segmentation and their behaviors at the core of its selection.

- Hypertrade’s Ariane 4S new generation of Category Management Platform allows you to automatically ingest an unlimited volume of data from various sources, delivering fast actionable sales and customer insights.

2. Planogram Optimization: The Art of Product Placement

Planograms are the blueprints for your retail space, dictating how products are positioned on shelves and displays. Strategic planogram optimization goes beyond aesthetics, influencing customer behavior and ultimately driving sales.

Benefits:

Impulse Purchases: By placing high-margin items at eye level and strategically positioning complementary products together, you can nudge customers towards impulse purchases and increase overall sales value.

Traffic Flow Optimization: A well-designed planogram can guide customer flow throughout the store, ensuring they encounter key product categories and maximizing exposure to promotional items.

Improved Inventory Management: Effective planograms consider product size and weight, minimizing wasted space and ensuring optimal product visibility.

Technology Integration: Integrating AI and advanced data analytics with existing ERP and supply chain management systems can provide a seamless and efficient operation. These technologies can interact to produce dynamic and responsive planograms.

Where We Can Help:

- OPENCatman: A simple yet efficient and effective solution to build your planograms collaboratively.

3. Automatic Replenishment: Taking Inventory Management on Autopilot

Gone are the days of manual inventory checks and scrambling to prevent stockouts. Automatic replenishment systems leverage technology to streamline the process, ensuring shelves are always stocked with the right amount of product.

Benefits:

Reduced Stockouts: Automatic reordering prevents stockouts, ensuring customer satisfaction and preventing lost sales opportunities.

Minimized Overstocking: The system considers past sales data and forecasts to prevent overstocking, reducing storage costs and the risk of obsolescence.

Improved Efficiency: Automating inventory management frees up staff time for other crucial tasks like customer service or store maintenance.

Data Analytics: Advanced data analytics can further refine replenishment systems by analyzing trends, seasonality, and external factors to improve forecast accuracy.

Where We Can Help:

TRF Retail’s auto-replenishment engine articulates several algorithms to optimize sales forecasts, integrates all planogram dimensions, manages multi-ordering and delivery flows, and enables users to plan and manage external events.

The Power of the Trifecta: A Holistic Approach

The true magic lies in the synergy between these three strategies. Assortment rationalization ensures you have the right products; planogram optimization positions them for maximum impact; and automatic replenishment guarantees they’re always available. This holistic approach delivers a multitude of benefits:

Increased Sales: By offering the right products in the right places and ensuring consistent availability, you create a frictionless shopping experience that encourages customers to buy more.

Improved Efficiencies: Streamlined inventory management frees up staff time and reduces administrative burdens, allowing them to focus on higher-value activities.

Supplier Support: From assortment rationalization to optimized planogramming and accurate demand planning, suppliers often share these interests and are ready to support such initiatives.

Sustainability: Incorporating sustainable practices in assortment and supply chain management can enhance brand reputation and appeal to eco-conscious consumers.

Interested?