Customer behavior has changed drastically over the past few months. In many markets, we’ve observed similar trends: fewer shopping trips, larger baskets, and a shift toward essential products. For retailers, this means that previous assortments are no longer effective. Some products are selling less, while others are in higher demand but lack shelf space. As a result, inventory is growing, and margins are shrinking.

Our client faced these same challenges. In response, they acted quickly. They made the bold decision to temporarily disrupt their stores to build a more efficient and profitable assortment. The goal was simple: rationalize the assortment across all stores and formats.

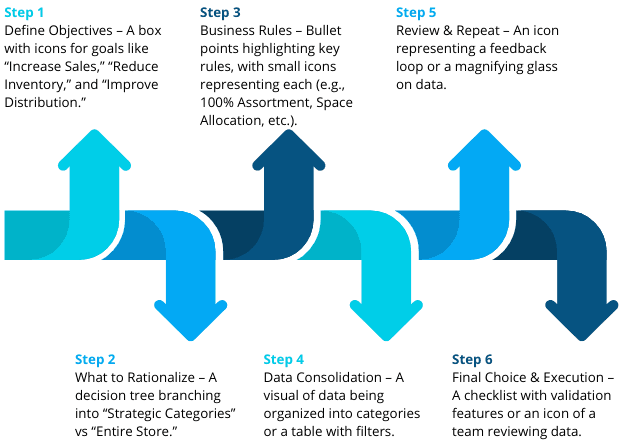

1. What Should Rationalization Deliver?

The first step was defining what the rationalization should achieve. After discussions, we set clear objectives:

- Reduce the number of SKUs.

- Increase sales per square meter.

- Free up space for top-selling items.

- Improve the supply chain.

- Reduce unnecessary inventory.

- Ensure 100% distribution of top items across all 90 stores.

By clearly defining objectives, retailers ensure that every decision aligns with their strategic goals, supported by tools like OKR software and data analytics platforms for precise goal tracking.

2. What Should Be Rationalized?

Once the objectives were set, the next question was: Should we focus on specific categories, or should we rationalize the entire store? Both options had pros and cons. Ultimately, we decided to review the entire store. This would allow us to set a strong foundation for future improvements.

Alternatively, we could have focused on:

- Reducing excess inventory.

- Simplifying the number of brands or price points.

- Aligning with a Good-Better-Best price structure.

The choice of which categories to rationalize lays the foundation for long-term retail success, with category management tools and data mining software guiding those critical decisions.

3. Define the Business Rules

Next, we worked with the client to define the business rules for the rationalization. These rules would guide both the current project and future assortment management. Key rules included:

- 100% of the assortment must be mandatory, even for items required in only one store.

- Space allocation must be defined by product type.

- There should be a maximum number of items per bay.

- We needed clear metrics to decide whether to keep or remove an item.

- Retain products tied to the “Housewife” and “Big Spender” segments, based on CRM data.

Strong business rules help guide decision-making and ensure consistency across all store formats, with rule-based engines and process mapping tools streamlining this setup.

4. Consolidate & Organize Data

With the business rules in place, we could begin working with the data. We organized it according to the merchandise hierarchy, ensuring we focused on the most relevant data.

To streamline the process, we added filters to guarantee:

- Items selected for smaller stores were also included in larger stores.

- Each selected item was available across all stores.

- Items fit within the allocated bays.

Organizing and consolidating data allows for more informed decisions and better inventory management, aided by data integration software and ERP systems for seamless data flow.

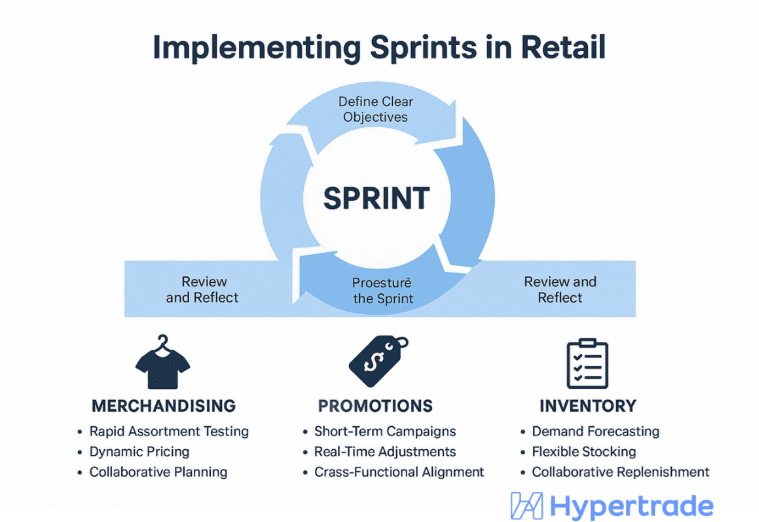

5. Review & Repeat

After the system generated suggestions for which items to keep and remove, we started the review process. We carefully checked the business rules, focusing on strategic items like those for the “Housewife” and “Big Spender” segments. We also used common sense. For instance, if a sub-category only had one product with minimal sales, should we keep it?

Once the review was complete, we were ready to send the final assortment proposal to the client.

6. Client Final Choice & Execution

To ensure independence in decision-making, we added a validation function to the tool. This would alert the team if they exceeded the maximum number of items per bay. The validation gave the client’s team full control, with clear visibility into the impact of their choices.

Empowering the client with clear decision-making tools ensures smooth execution and better outcomes, supported by project management tools and assortment optimization platforms for flawless implementation.

Maintaining Continuous Improvements

While rationalization is important, it cannot be done too frequently. Customer shopping behavior continues to evolve. To keep up, we set up a monthly review schedule focused on “Super Core Categories” (over 50% of sales) and “Core Categories.”

This process works across all store formats, ensuring consistency. It also helps category managers and suppliers align their strategies. As the tool evolves, 80% of the work will be automated, saving time and effort.

Ongoing adjustments and improvements keep the assortment fresh and aligned with evolving customer needs, facilitated by forecasting tools and CRM software to track and adjust strategies.